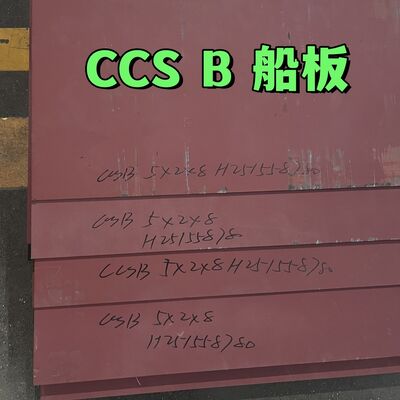

Pelat Baja Kelautan ABS CCS LR BV Grade A B AH36 DH36 EH36 untuk Pembangunan Kapal

Deskripsi Produk

Deskripsi Produk

| Standar |

CCS/ABS/LR/GL/BV/DNV/NK/KR/RINA |

| Material |

A/B/D/E,A32/D32/E32/F32,A36/D36/E36/F36,A40/D40/E40/F40,A131A/B/D/E/

AH32/DH32/EH32/AH36/DH36/EH36/AH40/DH40/EH40 NVA420/D420/E420,NVA460/D460/E460,NVA500/D500/E500,NVA550/D550/E550

|

| Grade |

A/B/D/E |

| Permukaan |

Dilapisi/Berminyak |

Kondisi Pengiriman:

| Variasi |

Kondisi Pengiriman |

| Pelat Grade A & B dengan h≤50mm |

Digulung panas, digulung CNC atau dinormalisasi |

| Pelat Grade D dengan h≤35mm |

| Pelat Grade D&E dengan h>35mm |

Dinormalisasi |

| Pelat Grade A32, A36, D32 & D36 dengan h≤25mm |

Digulung CNC, dinormalisasi |

| Pelat Grade A32, A36, D32, D36, E32 & E36 dengan h>25mm |

Dinormalisasi |

| Grade |

C |

Si |

Mn |

P |

S |

Als |

Ti |

Cu |

Cr |

Ni |

Mo |

Nb |

V |

| AH32 |

≤0.18 |

≤0.50 |

0.9~1.6 |

≤0.035 |

≤0.035 |

≥0.015 |

≤0.02 |

≤0.35 |

≤0.20 |

≤0.40 |

≤0.08 |

0.02~0.05 |

0.05~0.10 |

| DH32 |

≤0.18 |

≤0.50 |

0.9~1.6 |

≤0.035 |

≤0.035 |

≥0.015 |

≤0.02 |

≤0.35 |

≤0.20 |

≤0.40 |

≤0.08 |

0.02~0.05 |

0.05~0.10 |

| EH32 |

≤0.18 |

≤0.50 |

0.9~1.6 |

≤0.035 |

≤0.035 |

≥0.015 |

≤0.02 |

≤0.35 |

≤0.20 |

≤0.40 |

≤0.08 |

0.02~0.05 |

0.05~0.10 |

| FH32 |

≤0.16 |

0.1~0.5 |

0.9~1.6 |

≤0.025 |

≤0.025 |

≥0.015 |

≤0.02 |

≤0.35 |

≤0.20 |

≤0.80 |

≤0.08 |

0.02~0.05 |

0.05~0.10 |

| AH36 |

≤0.18 |

≤0.50 |

0.9~1.6 |

≤0.035 |

≤0.035 |

≥0.015 |

≤0.02 |

≤0.35 |

≤0.20 |

≤0.40 |

≤0.08 |

0.02~0.05 |

0.05~0.10 |

| DH36 |

≤0.18 |

≤0.50 |

0.9~1.6 |

≤0.035 |

≤0.035 |

≥0.015 |

≤0.02 |

≤0.35 |

≤0.20 |

≤0.40 |

≤0.08 |

0.02~0.05 |

0.05~0.10 |

| EH36 |

≤0.18 |

≤0.50 |

0.9~1.6 |

≤0.035 |

≤0.035 |

≥0.015 |

≤0.02 |

≤0.35 |

≤0.20 |

≤0.40 |

≤0.08 |

0.02~0.05 |

0.05~0.10 |

| FH36 |

≤0.16 |

0.1~0.5 |

0.9~1.6 |

≤0.025 |

≤0.025 |

≥0.015 |

≤0.02 |

≤0.35 |

≤0.20 |

≤0.80 |

≤0.08 |

0.02~0.05 |

0.05~0.10 |

| AH40 |

≤0.18 |

≤0.50 |

0.9~1.6 |

≤0.035 |

≤0.035 |

≥0.015 |

≤0.02 |

≤0.35 |

≤0.20 |

≤0.40 |

≤0.08 |

0.02~0.05 |

0.05~0.10 |

| DH40 |

≤0.18 |

≤0.50 |

0.9~1.6 |

≤0.035 |

≤0.035 |

≥0.015 |

≤0.02 |

≤0.35 |

≤0.20 |

≤0.40 |

≤0.08 |

0.02~0.05 |

0.05~0.10 |

| EH40 |

≤0.18 |

≤0.50 |

0.9~1.6 |

≤0.035 |

≤0.035 |

≥0.015 |

≤0.02 |

≤0.35 |

≤0.20 |

≤0.40 |

≤0.08 |

0.02~0.05 |

0.05~0.10 |

| FH40 |

≤0.16 |

0.1~0.5 |

0.9~1.6 |

≤0.025 |

≤0.025 |

≥0.015 |

≤0.02 |

≤0.35 |

≤0.20 |

≤0.80 |

≤0.08 |

0.02~0.05 |

0.05~0.10 |

Sifat Mekanik Pelat Baja untuk Pembangunan Kapal

| Grade |

Ketebalan (mm) maks |

Titik Luluh (Mpa) min |

Kekuatan Tarik (Mpa) |

Perpanjangan(%)

min

|

Uji impak V |

Uji tekuk dingin |

| Suhu(ºC) |

Rata-rata AKV |

b=2a 180° |

b=5a 120° |

| memanjang Min |

melintang Min |

| A |

50 |

235 |

400~520 |

22 |

- |

- |

- |

- |

d=2a |

| B |

50 |

235 |

400~520 |

22 |

0 |

27 |

20 |

- |

d=3a |

| D |

50 |

235 |

400~520 |

22 |

-10 |

27 |

20 |

- |

d=3a |

| E |

50 |

235 |

400~520 |

22 |

-40 |

27 |

20 |

- |

d=3a |

| AH32 |

50 |

315 |

440~570 |

22 |

0 |

31 |

22 |

- |

d=3a |

| DH32 |

50 |

315 |

440~570 |

22 |

-20 |

31 |

22 |

- |

d=3a |

| EH32 |

50 |

315 |

440~570 |

22 |

-40 |

31 |

22 |

- |

d=3a |

| FH32 |

50 |

315 |

440~570 |

22 |

-60 |

31 |

22 |

- |

d=3a |

| AH36 |

50 |

355 |

490~620 |

21 |

0 |

34 |

24 |

- |

d=3a |

| DH36 |

50 |

355 |

490~620 |

21 |

-20 |

34 |

24 |

- |

d=3a |

| EH36 |

50 |

355 |

490~620 |

21 |

-40 |

34 |

24 |

- |

d=3a |

| FH36 |

50 |

355 |

490~620 |

21 |

-60 |

34 |

24 |

- |

d=3a |

| AH40 |

50 |

390 |

510~660 |

20 |

0 |

41 |

27 |

- |

- |

| DH40 |

50 |

390 |

510~660 |

20 |

-20 |

41 |

27 |

- |

- |

| EH40 |

50 |

390 |

510~660 |

20 |

-40 |

41 |

27 |

- |

- |

| FH40 |

50 |

390 |

510~660 |

20 |

-60 |

41 |

27 |

- |

- |

Dimensi yang Tersedia untuk Pelat Pembangunan Kapal

| Item |

Ketebalan (mm) |

Lebar (mm) |

Panjang/diameter koil(mm) |

| Pelat pembangunan kapal |

6~50 |

1300~3000 |

3000~15000 |

| Koil pembangunan kapal |

6~20 |

1500~2000 |

760+20~760-70 |

Kondisi Tambahan

UT (Pemeriksaan Ultrasonik),AR(Hanya Digulung Panas),TMCP(Pemrosesan Kontrol Mekanik Termal),N(Dinormalisasi),Q+T(Dikeraskan dan Dilunakkan),

Uji Arah Z(Z15,Z25,Z35) ,Uji Impak Takik Charpy V, Uji Pihak Ketiga (seperti Uji SGS), Dilapisi atau Peledakan Shot dan Pengecatan.

Ketentuan Lainnya

A)Rincian Pengemasan: Pengemasan ekspor standar yang layak laut atau sesuai kebutuhan.

B)Waktu Pengiriman:30-50 hari, 7 hari untuk barang stok.

C)Pelabuhan Pemuatan:Shanghai ,Tianjin, Qingdao.

D)Kemampuan Penawaran:5000MT/Per Bulan.

E)MOQ:1 Pcs.

Pengemasan & Pengiriman

Pengemasan: pengemasan ekspor standar, atau sesuai kebutuhan pelanggan

Pengiriman: Kapal curah atau Kontainer, sesuai dengan produk dan kebutuhan pelanggan

FAQ

1.Apakah Anda akan mengirimkan barang tepat waktu?

Ya, kami berjanji untuk menyediakan produk kualitas terbaik dan pengiriman tepat waktu tidak peduli jika harga berubah banyak atau tidak, Kejujuran adalah prinsip perusahaan kami.

2.Bagaimana saya bisa mendapatkan penawaran Anda sesegera mungkin?

Email dan faks akan diperiksa dalam 24 jam, sementara itu, skype akan online dalam 24 jam Harap beri tahu kami informasi pesanan tentang kuantitas, Spesifikasi (jenis baja, bahan, ukuran) dan pelabuhan tujuan, Anda akan mendapatkan harga terbaru.

3.Bagaimana dengan sampel jika saya butuhkan?

Sampel akan ditawarkan secara gratis jika Anda membutuhkannya, tetapi biaya pengiriman akan ditanggung oleh pelanggan kami. Jika kami memiliki kerjasama,

biaya pengiriman akan ditanggung oleh perusahaan kami.

4.Bagaimana dengan MOQ?

Umumnya, pesanan percobaan akan diterima. MOQ dapat dikonfirmasi sesuai dengan produk yang berbeda. Misalnya, MOQ PPGI adalah 10MT.

5.Bagaimana dengan waktu pengiriman?

Dalam 15-30 hari setelah menerima deposit atau L/C pada pandangan. Tentu saja, detailnya akan dikonfirmasi oleh kuantitas dan produk yang berbeda.

6.Bagaimana cara memesan?

Silakan kirimkan pesanan pembelian Anda melalui email. Atau Anda dapat meminta kami untuk mengirimkan faktur proforma untuk pesanan Anda. Kami

perlu mengetahui informasi berikut untuk pesanan Anda.

7.Apa ketentuan pengiriman?

1. Kapal kontainer 2. kapal curah 3. Kereta

8.Apakah Anda memiliki Sertifikat Uji Pabrik Bahasa Inggris?

Ya, itulah yang kami berikan jaminan kepada klien kami

9.Apakah Anda menerima inspeksi pihak ketiga?

Ya, tentu saja kami menerima.

Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!  Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!